Rock and natural stone

Constructing a deep-shaft or underground mine changes the area of tension and field of stress of the surrounding mountain area.

Rock mechanics is tasked with investigating the mechanical behaviour of the rock as a result of this redistribution of stress.

Modelling includes the idealisation of complex empirical phenomena with respect to material behaviour, the static system and the stress values.

Determining the material constants is one of the first steps in this modelling process.

Geological-Petrographic Parameters

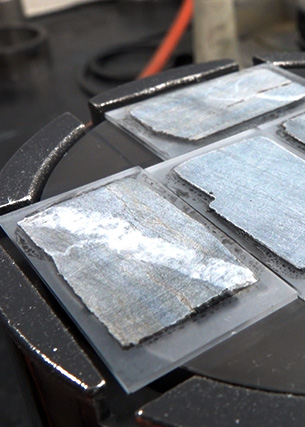

Thin section sampling

Thin section analysis is an important tool for describing, classifying and understanding rocks.

Mineral composition and microstructure can be described quantitatively and qualitatively. With the help of a carrier material, thin sections can also be produced from unbound materials such as gravel or sand and examined under the microscope.

The Hagerbach Test Gallery produces both water-based and water-free thin sections professionally, cost-effectively and efficiently.

Loose rock analyses

Sieve analysis

Using a series of sieves with decreasing mesh size, the sample material is sorted according to grain size.

The sieve residues are weighed and graphically represented as a so-called grain distribution curve, whereby the curve shows the passage in mass percentages as a function of the sieve opening (cumulative curve).

This method is used to analyse samples with grain sizes between Ø 125 and 0.063 mm.

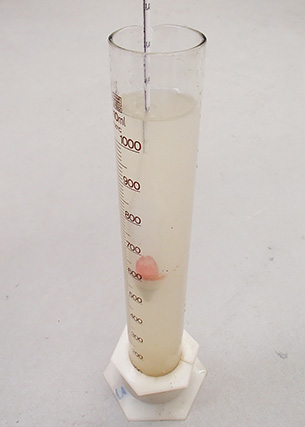

Slurry analysis (hydrometer)

From a grain size of < 0.125 mm, the hydrometer method can be used to determine the the hydrometer method can be used to determine the particle size distribution.

The material to be analysed is slurried in a tall measuring cylinder and the grain size distribution is determined with the help of the hydrometer based on sedimentation over time.

Classification according to USCS

Recording and classification of unconsolidated rocks based on soil mechanical properties. Parameters:

- Grain size distribution (sieve & slurry analysis),

- consistency limits according to Atterberg,

- organic admixtures.

Rock mechanics laboratory test according to SN or ASTM standard

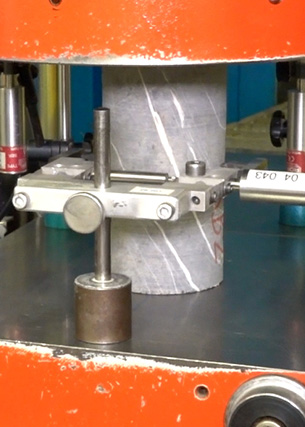

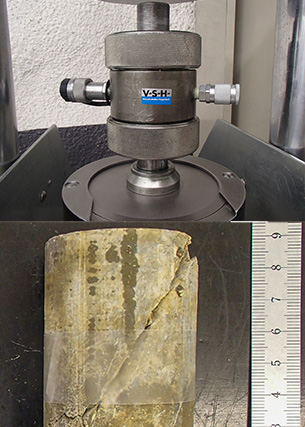

Uniaxial compressive strength

In the uniaxial compression test, a cylindrical specimen is loaded in the axial direction until it breaks. The specimen is loaded axially up to a stress level of 25 - 75 % of the expected fracture stress and then unloaded again.

Axial and circumferential strain transducers continuously record the changes. Various parameters can be determined from the loading and unloading loops. The Young's modulus describes the linear-elastic relationship between the applied pressure and the resulting deformation.

The Poisson's ratio results from the relationship between the longitudinal and transverse deformation.

Triaxial compressive strength with multi-stage technique

The triaxial compression test is used to determine the rock properties at constant lateral pressure. The test specimen is loaded axially at a defined lateral pressure until shortly before fracture. Then the lateral pressure is increased in steps and the test specimen continues to be loaded axially at the same time. During the subsequent stepwise unloading, the same lateral pressures are applied and thus the residual strength of the specimen is determined.

The triaxial compression test also provides information about the shear parameters (cohesion and friction angle).

The advantage of this method is that the grain structure is hardly disturbed by repeated loading and several triaxial compression several triaxial compression tests with different load levels can be carried out on one test specimen.

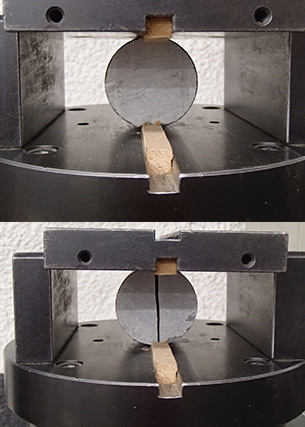

Split tensile test

In the split tensile test, the test specimen is loaded on two opposite sheath lines (line load) until it breaks.

The compressive force triggers tensile stresses in the transverse direction inside the test specimen.

The theoretical magnitude of the transverse tensile stress at the onset of the fracture is assumed to be the splitting tensile strength.

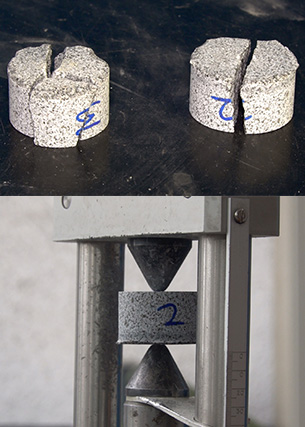

Point load test

In the point load test, the test specimen is loaded between two load application peaks until it breaks.

The measured breaking load results in an index value for the strength of the rock.

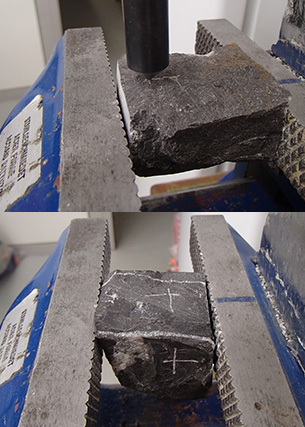

Cerchar abrasiveness index

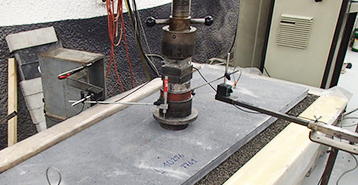

The Cerchar Abrasivity Index is defined as the wear of a metal tip when scratching the rock.

A standardised metal tip is used to scratch the freshly broken surface of the rock with a load of 7 kg. With a new metal tip, this process is repeated on 3 fractured surfaces, each in 2 different directions. different directions.

The diameter of the resulting flattening is measured with a monocular and reported as the Cerchar abrasiveness index.