Prototyping

The continuously growing environment in the Hagerbach Test Gallery offers optimal conditions for testing prototypes (devices, machines) as well as structural implementations (buildings, components, installations and system solutions) and their functionality.

- Realistic environment: In the extensive network with its versatile expansion stages, surfaces and different profiles, there are always requirements that can be applied to the individual needs of the prototypes and on a scale of 1:1.

- Constant climate: Each tunnel section has its own constant climatic conditions. Depending on requirements, a prototype can be positioned accordingly.

- Accessibility: We offer flexible positioning according to your needs, discreet as well as audience effective, in a test environment accessible all year round.

We will be happy to integrate your prototype into our gallery tours and help you present it to a wide target audience. (Annual number of visitors: approx. 18,000)

Watch the report made by the Swiss news magazine "10vor10"

Use Case CIFA

The Hagerbach Test Gallery is the ideal place to test a prototype machine without the time constraints and hustle and bustle of a real tunnel or mine.

In addition, the gallery has its own batching plant and accredited materials testing laboratory, providing a high degree of flexibility for a prototype trial.

CIFA designs and manufactures a complete range of machines for production, transport, and placing of concrete. Since 1928, CIFA has been a technological leader in the concrete supply chain. With its award-winning European design technology, CIFA has been in the construction equipment market for more than 90 years with the commitment to safety, machine performance improvement, work productivity increase, and ease of operation.

CIFA S.p.A. chose to perform the test of "Mamba “, a fully new shotcrete machine prototype, at the Hagerbach Test Gallery, where the machine could be tested in different scenarios. It was tested with different qualities of concrete (from dryer to more wet) and with metal fibres to stress out the new boom and the existing pumping unit. The boom was extended to full height and the machine was manoeuvred and worked in narrow galleries. Finally, the breaks were tested on an 11˚ slope. A very positive test outcome, drove CIFA to launch the machine at Bauma 2022 and phase this model in full production.

Testimonial from CIFA

We chosen the Hagerbach Test Gallery, after several evaluations, because it is a unique integrated solution to test a new machine in a real working condition, with no compromise.

Well appreciated are the professional of the workers, the high standards in terms of security, and the flexibility to adapt to our own needs.

Reference projects

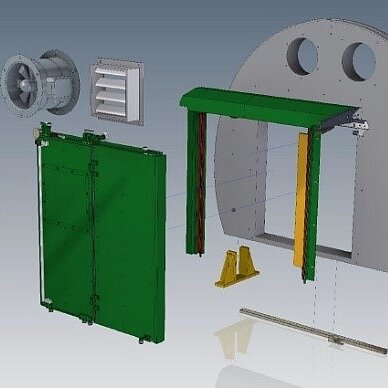

Plug-in Crosscut Element (PCE)

As a structural connection between the tunnel tubes, crosscuts play a central role in the safety concept of long tunnels: In the event of an incident, they enable rapid self-rescue and evacuation of persons from the event tube to a safe area. Access is provided via so-called crosscut doors, which are installed on both sides.

The SCAUT consortium has developed an innovative solution and built the prototype in Hagerbach

Underground Green Farming

With the concept study "Underground Green Farming" SCAUT wants to investigate the use of underground space for the production of food. Ecological aspects play an important role (short transport routes, closed cycle management, optimisation of production conditions, etc.).

The prototype was built in the Hagerbach Test Gallery. The pilot plant with trout and lettuce from the tunnel serves the consortium for the development of the study.

RhB prototype of the standard tunnel construction

Due to its age, most of the 115 tunnels on the Rhaetian Railway (RhB) network will have to be renovated over the next few years. RhB developed a new, standardised repair procedure for this purpose on the prototype in the Hagerbach Test Gallery: the "standard tunnel construction".

Further examples:

- Underground data center

- Sewerage training system

- Tube garden

- Security doors

- Dynamic escape route lighting