Fire Testing & Fire Resistance Laboratory

We are the right partner, if it is about fire resistance tests in Switzerland!

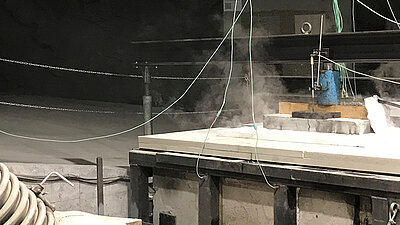

The Hagerbach Test Gallery offers an ideal setting, a lot of know-how and suitable accreditation in regard to fire resistance tests.

With more than 10 years of experience, we gained experience in many different testing situations such as:

- Development testing on new safety systems

- Testing for scientific research projects

- Accredited fire resistance tests on building materials and elements (STS 0060)

Examples of fire tests that can be performed customer-specifically on a 1:1 scale:

- Test on batteries for electric vehicles (BEV).

- Building materials such as wood, plastic, natural stone, composites, polymer concretes, ultra-high strength concretes, special mortars, wood fiber concretes, insulating concretes, manhole covers, coverings, etc.

- Proof of functionality of systems after thermal exposure (e.g. lids, manholes, manhole covers, etc)

Questions & Answers

We are accredited according to EN 1363-1 and EN 1365-2.

- General fire resistance tests to determine the spalling behaviour and fire resistance of concrete formulations, mortars and concrete replacement systems.

- Fire resistance tests on concrete (spalling behaviour).

- Fire resistance tests on special elements (without own product standard).

- Fire resistance tests for development and research purposes.

- Fire resistance tests on cantilever slabs (under load).

- Fire resistance tests according to customer specifications.

- Special tests on special materials and systems, such as wood, plastic, natural stone, composites, polymer concretes, ultra-high-strength concretes, special mortars, wood fibre concretes, insulating concretes, manhole covers, coverings, etc.

- Tests to prove the functionality of systems after thermal exposure (e.g. lids, hatches, manhole covers, etc).

Depending on the temperature curve applied, tests with a duration of 20 min to 180 min are possible. At the customer's request, the test can be extended beyond this every minute. In the case of accredited tests, it should be noted that the test specimens must be stored in the VSH under special climatic conditions for at least 100 days after manufacture before they may be tested. At the customer's request and outside of accredited tests, a shortening of the conditioning period is possible.

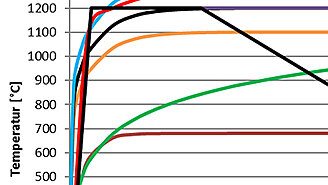

ETK, RWS, HC, HCmod, HCinc, EBA, ZTV-ING, outer burn curve.

Tests according to special temperature curves are possible on customer request.

The measurement signals from the sheath thermocouples are converted and displayed in °C at a central measuring station.

A computer records all temperatures every 15 s or 30 s and keeps a record of them.

The furnace temperature is controlled by the test engineer according to the specified temperature curve.

Test specimen dimensions 2100 x 1900 x 300 mm (L X W X H)

Storage of the test specimen under special climatic conditions.

Storage in ambient air with 50 % relative humidity at a temperature of 23 °C.

The masonry kiln has internal dimensions of 1500 x 1500 x 850 mm (L x W x H).

- Concrete

- mortar

- concrete replacement systems

- HFB

- UHFB

- fibre concretes

Name and address of the testing laboratory and its accreditation and/or number of the notified body, as applicable;

- name and address of the client;

- date of test;

- unique reference number of the test;

- name of the manufacturer of the specimen (if known) and of the products and components used in the construction, including identification marks and trade names;

- design details of the specimen with description and drawings including the main characteristics of individual parts.

- the relevant properties of building materials or constituents, such as density, thickness, moisture content, organic matter content, etc., which contribute to the reaction to fire performance of the test specimen.

- Method of assembly and installation of the test specimen;

- details of conditioning of the test specimen prior to testing;

- details of the involvement of the testing laboratory in the selection of the test specimens;

- for load-bearing members, the load applied to the test specimen, the basis for its calculation according to the client's specifications and the load constellation, including the number and distribution of load application points;

- support and restraint conditions applied and the justification for their selection;

- details of the location of all thermocouples, pressure and deflection gauges attached to the specimen. Drawings shall be included clearly indicating the location of the various devices and identifying the devices with respect to the data provided;

- ambient temperature of the test laboratory at the start of the test;

- pressure conditions within the test furnace with respect to the location of the test structure;

- temperature time curves of the furnace heating conditions;

- reasons for validating the test if the permissible deviations of the temperature-time curve, pressure conditions or environmental conditions of the test laboratory are unintentionally exceeded;

- tabular and/or graphical presentation of the measurement results of all pressure and deflection measuring devices, thermocouples on the non-flame side and, if applicable, the internal thermocouples;

As a rule, you will receive the test report after a few days. Depending on the workload of the laboratory, the waiting time can be up to 3 weeks.

Yes. At the customer's request, you can accompany the test in our fire laboratory on site.

Yes, we offer new possibilities in VSH via live streaming and direct connection to the test engineer.

2 camera settings and tracking of the temperature curve and measurement data in real time are possible.

Via plates or sheathed thermocouples. Direct cable connection to the transmitter. Recording every 30 s.

With sheath thermocouples.

These are fixed in the formwork to the depth required by the customer before concreting the test specimen. Subsequent insertion of the thermocouples is possible by means of a special drilling and setting procedure.

4 FPP. If there is a lack of experience with the building materials used, a screening or comparative test is recommended.

Up to a maximum of 4 different concrete or mortar mixtures and up to 2 surface applications can be compared during one test.

The Hagerbach Test Gallery according to customer specifications or customer itself.

300 x 300 x 250 mm (L X W X H)

No - possible at the customer's request, but not absolutely necessary.

Synthetic microfibres have an even lower modulus of elasticity than synthetic macrofibres.

They are mainly used to reduce early shrinkage and to improve fire resistance due to their low melting point (160 °C). Furthermore, these fibres significantly increase impact resistance and are also non-corrosive.

Synthetic microfibres make concrete much more fire resistant. The fibres are added to the concrete mix during its production.

In the event of a fire, the higher permeability of the fibres reduces the vapour pressure in the concrete so that there is no or very little spalling, which ensures the stability of the structure during and after the fire.

The dosage of microfibres in the test specimen can be adjusted according to customer requirements.

On request, we can process the customer's own microfibres. Please provide us with these before the test specimen is created. We also process microfibres from renowned manufacturers from all over the world.

Special building projects bring with them special issues - this also applies to fire protection.

In large-scale projects, more and more solutions are being used that cannot be covered by the usual standards tables or regulations.

In the Hagerbach test tunnel, project-specific questions concerning fire protection can be answered with appropriate, flexible test setups. This is possible even if no relevant standards are available.

The prices vary depending on the test duration and fire curve. Basically, the prices of a fire resistance test according to the ETK temperature curve and a test duration of 60 min start at approx. CHF 8,300.

Additional costs arise, for example, due to the manufacture of the test specimen, the use of additional thermocouples and the work involved in setting them up before or after the manufacture of the test specimen, for tests with higher temperature curves or for tests with special setups according to customer requirements.