Concrete is one of the elementary materials in modern construction and enjoys great popularity thanks to its flexibility and versatility, but also because of its technical properties. Since its foundation, the Hagerbach Test Gallery (VSH) has been intensively involved in the targeted development of formulas for modern and optimised concretes, in process innovation and in reliable quality assurance and testing. Our own tunnel concrete plant with the latest control system also offers development opportunities to produce concrete recipes 1:1 real scale and to test it. The accredited building materials laboratories round off the range of services. Our experts are happy to help with technical questions regarding the testing of rock, stone, concrete and elements.

(1) Robot sprayed concrete tests in the VSH

(2) Concrete technological development under realistic but constant conditions in the test gallery.

The development of concrete as a modern structural building material was of great importance, especially for the construction of permanent tunnel structures. From the very beginning, innovative engineers and contractors have used our test gallery to further develop the process and quality of modern concrete, especially in terms of shotcrete (sprayed concrete) technology.

Leading international companies such as Sika, Master Builders, Mapei, Grace, Meyco, Putzmeister and Normet make intensive use of the 1:1 test possibilities to put new products through a hardness test and ultimately bring them to market.

For optimum documentation and assurance of the results, the establishment of VSH's own building materials testing laboratory began in the late 1970s. As early as 1984, the laboratory was able to obtain accreditation from the Swiss accreditation body SAS and thus offers numerous accredited tests for rock, aggregates and concrete as well as specific element tests. The VSH experts also played an active role in the country's standardization bodies to advance the knowledge and experience needed to improve the quality of modern building materials.

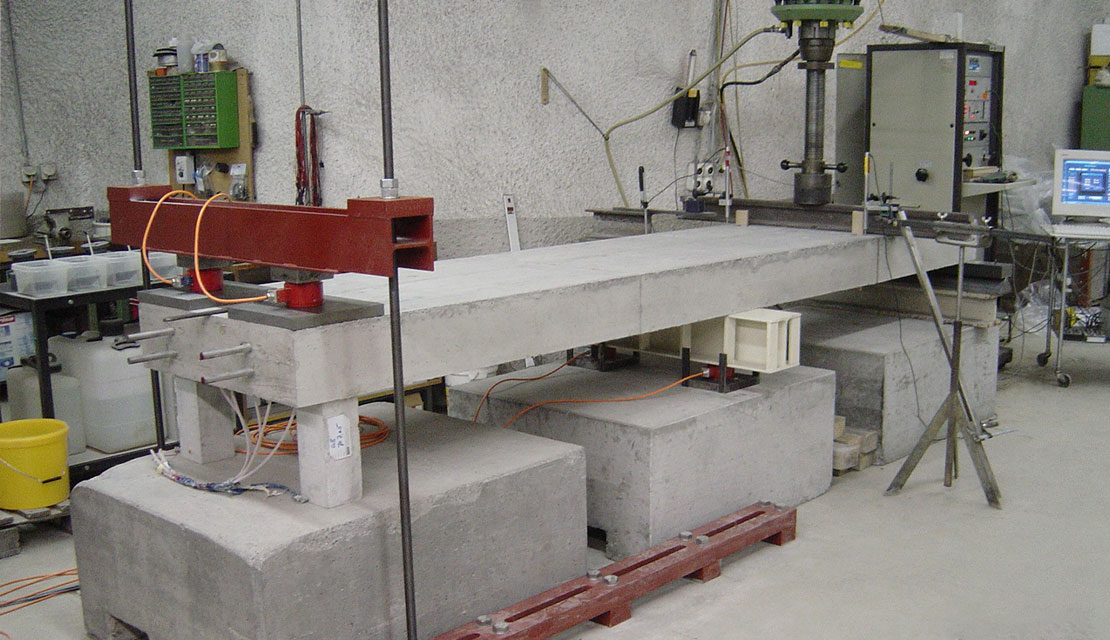

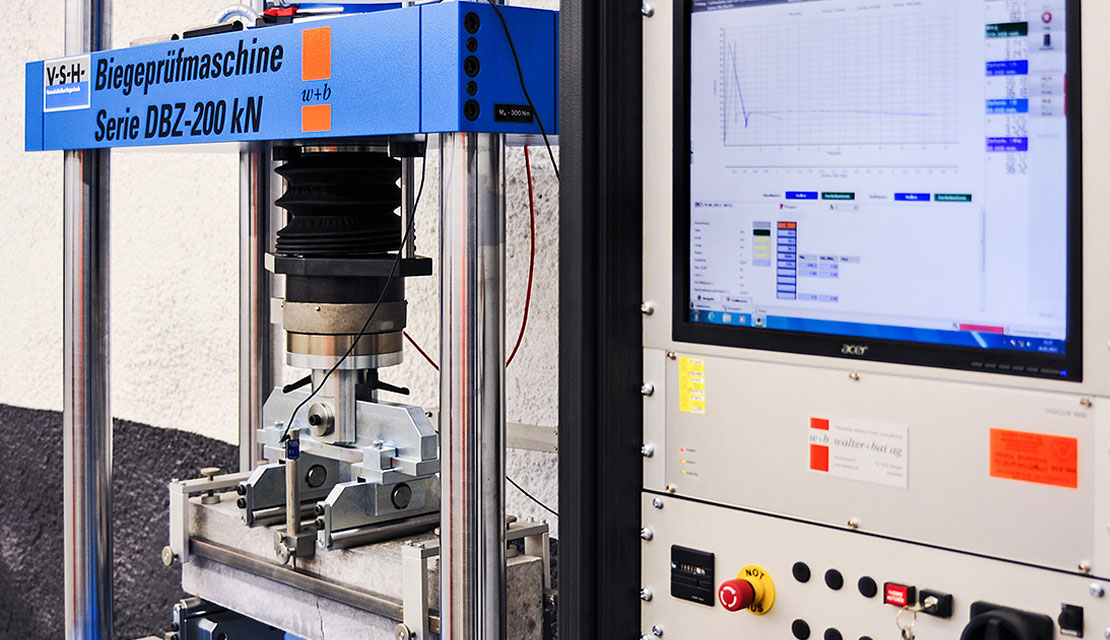

(1+2) Insight into the building material test laboratory

Reto Niederhauser, head of the building materials testing laboratories, underlines: "As a reliable partner of the construction industry, we built on the experience of our team to ensure top quality, practical suitability and transparent commitment.

The laboratory services at the VSH cover the latest developments in the field of concrete. In addition to durable concrete solutions, these include special applications such as fiber-reinforced shotcrete or ultra-high strength, reinforced concretes. The portfolio also includes shotcrete membranes, coatings, concrete coatings, repair materials and, last but not least, condition assessment of concrete structures.

Impressions of the concrete plant in the VSH

The construction of the major alpine tunnels Furka, Vereina, Lötschberg, Gotthard and Ceneri has advanced the development of specialised cements, additives and concretes with optimised properties. In the 1990s, the company's own concrete plant with ten gravel silos was put into operation for research and testing purposes.

The concrete mixing plant, designed for underground operation, consists of the following components:

- Ten silos for aggregates (6 x sand, 4 x gravel)

- Two silos and screw conveyors for the cement discharge of big bags or bagged goods

- Dosing devices for additives

- Batch mixer Teka THZ 1500, 1.5 m3 capacity

- PC-supported Dorner Electronic system control

Up today, this system is regularly used for special developments, but also for concrete workshops. Equipped with the latest DORNER control system, the setup meets the requirements of modern concrete plants and is also suitable for the training of concrete machine operators.