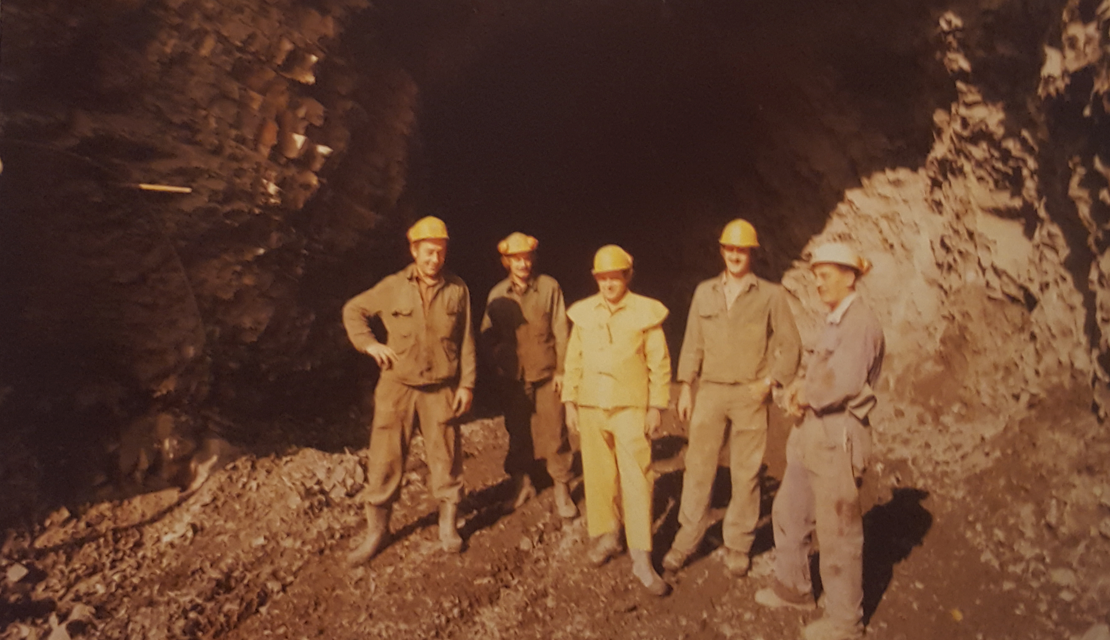

The foundation of the Hagerbach Test Gallery goes back to the Gonzen AG iron mine, which was closed in 1966. Together with the Swiss and foreign supplier industry, it carried out intensive research and development work in all areas of mining technology. After the closure, the feverish search for a new, suitable location for applied development work began.

The location of the former iron mine near Sargans at the intersection of two valleys, surrounded by high mountains and close to the cities of Zurich, St. Gallen and Chur, proved to be the ideal starting point for the search.

Finally they found what they were looking for at the edge of the Hagerbach gravel factory. The conditions at this site are favourable: a variability of geological conditions of very hard, abrasive and also very soft rock creates ideal boundary conditions for drilling and blasting tests of any dimension. Furthermore, the excavated material from the tunnel construction could be handed over to the nearby gravel factory for disposal. The sufficient distance to settlements and villages as well as the generous area in front of the gallery portal also spoke in favour of the current location in the village of Flums, which is only a stone's throw away from Sargans.

Thus it came about that the first explosions were carried out at this site in spring 1970.

From the very beginning, the tunnel facility was used for research and development as well as training and educational purposes. Long-term planning of the tunnel system was and is therefore not possible. Instead, we have always tried to adapt existing or new system components as optimally as possible to the needs and requirements of the users.

This means that, on the one hand, tunnel systems were created whose geometric size was the result of a specific requirement and, on the other hand, that tunnel sections have served different purposes over the years. In this sense, the Hagerbach test gallery is never finished but is constantly being adapted to requirements. Some basic configurations are always followed, for example a design that allows a natural ventilation of all system parts.