Technology That Tracks

The Maya Train’s 42 X’trapolis electric trains from Alstom were built in the company’s local Ciudad Sahagún site, in the state of Hidalgo.

Article by Mary Jo Wagner

Mexico’s Tren Maya (Maya Train) has been lauded as “the most important public work in the world” by former president Andrés Manuel López Obrador. Designed to boost economic and social development in the country’s southeast – a decades-long underdeveloped region – the 1,500-kilometer railway connects cities and towns in the five states of Chiapas, Tabasco, Campeche, Yucatán and Quintana Roo, offering a never-before loop around the Yucatán Peninsula.

An ambitious endeavor in both scope and deadline, the progress of the estimated $20 billion project has been followed in international news, it’s been covered regularly in national news, and most importantly, its progression has been watched carefully by López Obrador as well as his successor President Claudia Sheinbaum.

That keen interest and expectation has put “off the rails” pressure on the myriad construction companies feverishly working to complete their respective sections of the railway. Of critical importance was to have one particular section of the Maya Train ready for a first inaugural departure on Dec. 15, 2023, a deadline set by López Obrador.

“Given the completion schedule set by the president, we had about 18 months to build our 228-kilometer section,” says Juan Suarez, chief surveyor for Mota Engil, a construction company based in Porto, Portugal. “That in itself is incredibly challenging, but we also had to manage complex logistics, and ensure the integrity of ecologically sensitive areas along the rail’s path, all while delivering quality work on schedule. But, no pressure, right?”

Knowing they’d need reliable support to help meet exacting design requirements and tight deadlines, and to sustain an intense pace, Suarez entered the field with technology that would provide efficiency and precision to survey crews and automated analytical and reporting tools to maximize efficiency in the office.

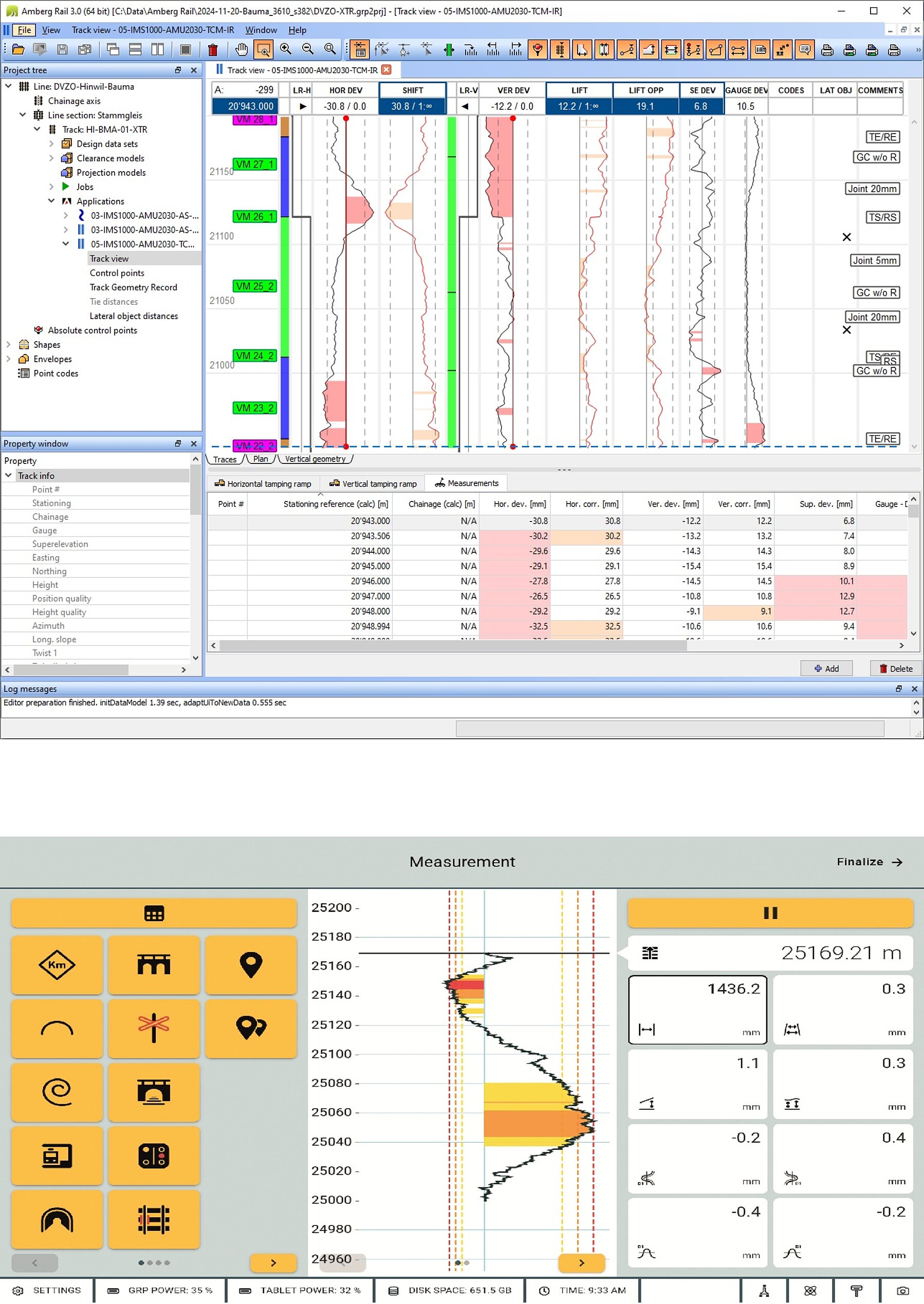

Proving just as critical as the ballast, sleepers and rails, Amberg Technologies’ GRP System FX railway surveying solution, a modular field-to-office system for acquiring precise track geometry and clearance analysis, provided Suarez and his teams the ability to steadily advance and complete section one of the railroad in record time, minimizing downtime, reducing costs and optimizing collaboration.

The oldest in Mexico and the American continent, the Cathedral of San Ildefonso is one of many heritage sites offered in Merida.

A transportation vision

Funded through the National Fund for the Promotion of Tourism, FONATUR, the Maya Train conventional passenger and freight line links the southeast’s main production and tourist centres. Combining both single and double track configurations, nearly the entire route is built on ballast with an international gauge of 1.435 mm, and is designed for a top speed of 160 km/h for passenger traffic and 100 km/h for freight. With 34 stations and 42 trains, the government estimates the new network will reduce passenger travel times by 46 percent and increase the speed of freight transport by up to 72 percent.

Because of the sheer scope of the project, it was divided into seven sections with development responsibility shared by FONATUR and the Ministry of National Defence (SEDENA). The first stage of the project (sections one to four) runs between Palenque and Cancún; the second stage (sections five to seven) runs from Cancún to Escárcega, bordering the Yucatán Peninsula in the south-southeast. Overall, about 44 percent – 680 km –of the entire rail line is electrified.

Although López Obrador initiated the construction of the railroad in June 2020 with a completion date of October 2022, legal challenges and environmental concerns halted and delayed work for nearly two years.

Given the shortened timeline, the construction companies responsible for building the president’s vision recognized that their approach would need to be an electrified one as well.

Tech that tracks

“Depending on circumstances, constructing four kilometers of railway can typically take around nine months,” says Suarez. “We had a little over a year to complete nearly 230 kilometers. So we knew conventional methods of manual levelling, prisms, gauge bars and measuring cords would not allow us to finish the railroad on time. We needed reliable and flexible technology that would let us be responsive, quick, highly productive and precise.”

Already equipped with one IMS 1000 railway surveying system from Amberg Technologies, a Switzerland-based leading provider of civil infrastructure solutions, Suarez acquired two additional IMS 1000s and one GRP 1000 railway surveying solution from ACRE Surveying Solutions, a local surveying equipment provider and Amberg Technologies distribution partner. Both modular systems provide reliable and highly precise geometry information during the construction, maintenance and inspection of railway tracks. And with the field and office Amberg Rail software, crews can automate data capture, calculations and reporting.

“As this was the first railway project in Mexico for me, there was going to be a lot of unpredictability,” says Suarez. “So any source of predictable consistency would be an asset. On a scale of one to ten, I knew that Amberg’s reliable performance would be a ten.”

The challenge would be transitioning from manual, traditional approaches to automated measuring equipment and techniques – a training and tech support task that largely fell to ACRE. Although many of the international companies’ crews were familiar with Amberg Rail equipment, the GRP 1000, IMS 1000 and IMS Track Pro, a recent advancement for as-built rail surveys, would be new technology to Mexican survey teams.

“Going from using manual methodologies to these advanced trolley systems requires adaptability,” says Roberto Chinarro, a rail survey manager with ACRE. “However, these incredibly user-friendly and proven instruments are easy to learn and users quickly see the efficiency, quality and productivity advantages they provide in the field. And then interest in the machinery grows quickly.”

Indeed, although Suarez was the first to introduce the Amberg IMS system to Mexico, it wouldn’t be long before word of his section’s expedited progress travelled to the other sites. Calls for the same equipment would quickly result in about 40 of Amberg Rail systems being delivered to the field, making them as common as tamping machines.

“The GRP 1000 and IMS 1000 not only provide highly precise geometry information during the construction and inspection of railway track, they can be optimally adapted to suit individual requirements,” says Suarez. “In addition, with the IMS solutions, they have one instrument that can be used for both construction and maintenance of the tracks once they’ve finished.”

An ACRE representative guides Maya Train crews through the Amberg IMS Track Pro rail measuring system.

Laying tracks

Mota Engil was awarded two portions of the Maya Train project: section one and part of section five. The most southern of the seven sections, section one runs north from Palenque to Escárcega and includes stations and stops in the states of Chiapas, Tabasco, and Campeche. Section five’s route is a 110-km stretch that connects Cancún and Tulum and has some of the most challenging topography due to fragile karst terrain and intricate cave and cenote systems.

Suarez was responsible for coordinating and managing the surveying tasks on section one and supervising a ground and office crew of about 70. In addition to laying 228 km of single ballast track, they also had to construct four stations, two stops and three viaducts, as well as underpasses, overpasses, overhead water collectors and a lengthy bridge at Boca del Cerro. To bring the significant work site down to manageable size and cover more ground, Suarez divided the overall section into three relatively equidistant parts and centralized office operations at Palenque.

To ensure they stayed on track, he created three Amberg teams of four crew, including a surveyor and survey assistant, none of whom had used a GRP 1000 or IMS 1000 before. With help from ACRE, after two days of training, field crews were ready to use the trolleys and the in-field software.

“ACRE’s dependable tech and training support was critical to aid our non-stop operations,” says Suarez. “It was particularly important to have reliable technology and on-call support because we were so remote.”

With an approach that combined the steadfast precision and efficiency of the Amberg IMS 1000 and the GRP 1000 and the tailored Rail software platform, Suarez’s dispersed survey teams successfully supported and validated the daily routines of rail laying, inspecting, and reporting.

The Amberg IMS Track Pro is a rail measuring and inspection system for both construction and maintenance.

Real-time results

Once a segment of rail was positioned, the Amberg survey crews inspected and verified the laid track predominantly using the IMS 1000 solution, a measuring trolley that offers precision sensors for gauge, superelevation, curvature, and distance, as well as a ruggedized tablet running the Rail software.

Placing the instrument on the track, the surveyor accessed the theoretical railway design loaded on the field tablet and used the on-board total station to collect a georeferenced control point from the pre-established network of over 3,000 control points. Pushing the trolley along the 1435-mm-wide rails, the machine’s sensors continuously captured and measured the relative track geometry in 3D and instantly logged any defects or deviations according to EN-13848 or user-defined standards. With the movement and orientation advantage of the trolley’s inertial measurement unit (IMU), teams could collect up to 60-m of data before needing to acquire the next control point. Consistently measuring to maximum accuracy, Amberg teams inspected and verified between 5-10 km of track each eight-hour shift, seven days a week.

“Measuring the gauge, superelevation and curvature with traditional, manual methods would have required us to go over each segment three to four times to ensure relative accuracy, and the data wouldn’t be in 3D,” says Suarez. “With the IMS 1000, a single Amberg team can do the work of three crews. We have the theoretical layout on the field tablet, we obtain the measurement data in a single pass and we can compare it in real time with the theoretical data. It’s seconds compared to multiple minutes, greatly simplifying the workflow and eliminating mistakes.”

The Amberg technology also enabled them to continue work through the night, with the only risk being unwanted snakes or other critters temporarily halting work.

“The IMS 1000 has its own LED lights so our crews could perform just as effectively as they did in daylight,” says Suarez. “It not only allowed us to work eight hours on the rail nonstop, it enabled me to maintain 24-7 shifts, which was key to us delivering on time.”

Data loops

At the end of each shift, the field data was sent electronically to the central office in Palenque for processing.

Using Amberg’s customized rail software platform, the field measurement data was downloaded to run analyses and calculations for producing tailored reports. The software automatically analyzed data showing the track gauge, superelevation, curvature, horizontal position, and elevation and automatically calculated any deviations from the design. All of that data was compiled in a pre-designed reporting template and provided to the track production manager, who verified possible track deviations and corrected them if necessary. Once adjustments were made, the Amberg team then conducted another inspection survey to confirm its accuracy.

Daily reports showing progress and verified kilometers of track were also provided to the Mexican government for approval.

“What's so magnificent about the software is we have accurate data and answers immediately,” says Suarez. “Without it, we’d be spending long hours calculating and re-calculating. With automated computations, it eliminates human errors and we can make decisions more quickly, even in the field if necessary. We can also export the data in whatever format the tamping machines need to ensure streamlined operations.”

After a solid year of measuring, inspecting and verifying round the clock, Suarez and his crews successfully connected Palenque to Escárcega, just in time for López Obrador’s first inaugural ride in December 2023. Although Suarez was not on board, he didn’t need the ride to appreciate what they accomplished.

“We made many good calls on this project,” he says. “But one of the best was choosing the Amberg equipment. We ushered in a new approach to as-built rail surveying––not a single surveyor has returned to manual methods. And without it, we wouldn’t have met our deadline, and we would’ve needed an order of magnitude more crew, more equipment and more time.”

As the last remaining work continues on sections five, six and seven, teams responsible for maintaining the completed railway portions are now benefitting from the continuity of the Amberg IMS 1000 and IMS Track Pro measuring equipment, creating a streamlined workflow as smooth as the Maya Train ride itself.